| Equipment List | Panasonic MAG welding machines: 120pcsPanasonic TIG welding machines: 110pcs Welding robots: 20pcs |

| Material | Carbon steel, alloy steel, aluminum plate, stainless steel, SECC, SGCC or customized |

| Shape | According to drawings |

| Quality control | ISO 9001:2015, factory audited by Bureau Veritas |

| Tolerance | +/-0.5~1.5mm |

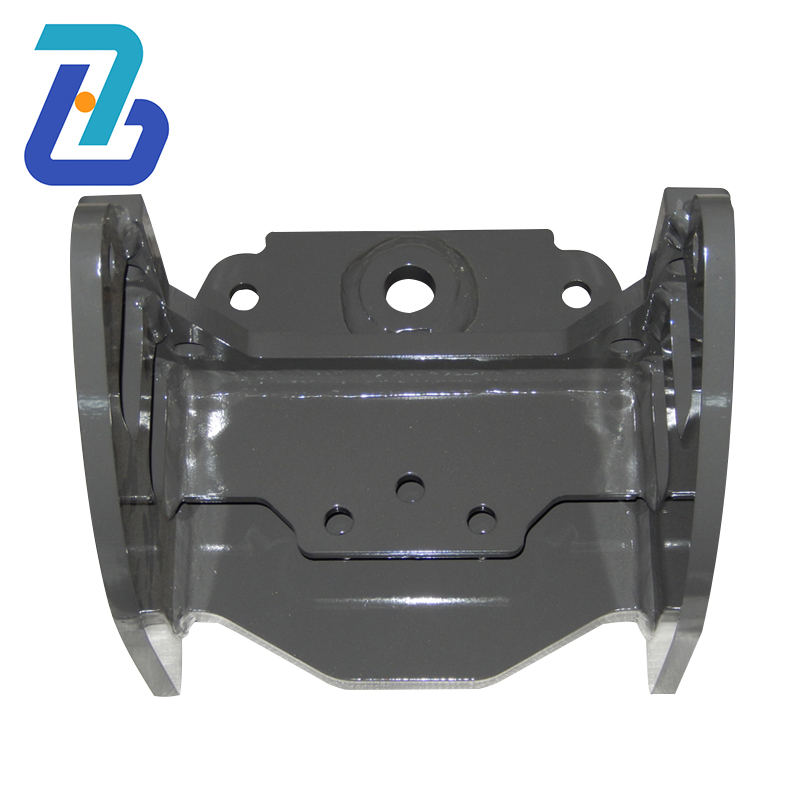

| Manufacturing process | Design-CNC laser cutting/flame cutting/stamping-forming/bending-CNC machining –welding-surface treatment-assembling-packing |

| No. of employees | 160 trained workers |

| Export Percentage | 40% |

| Sample time | 7 -14 days |

| Main market | North America, Europe, Oceania, domestic market |

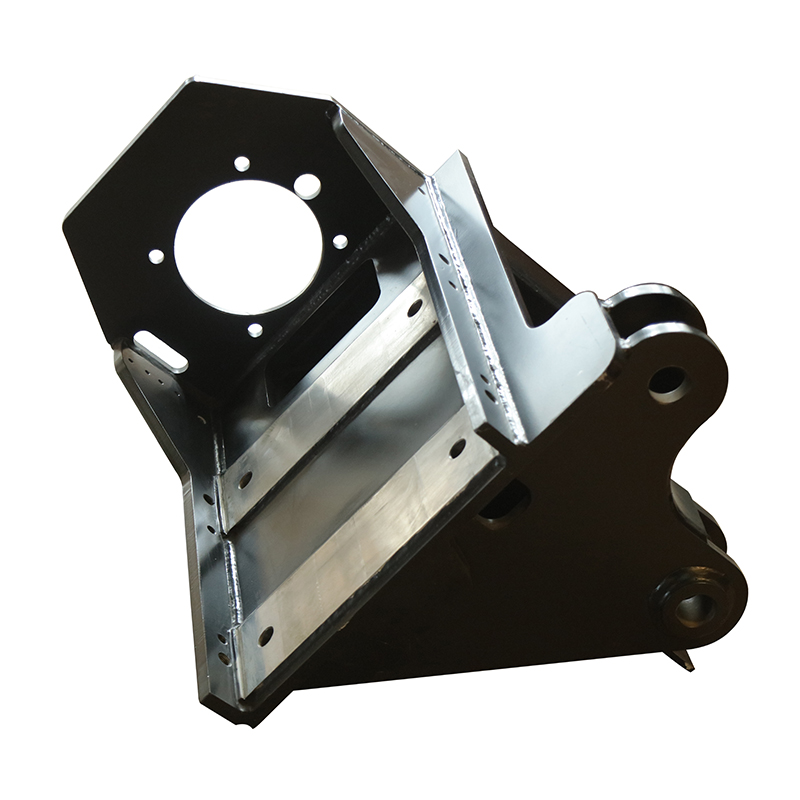

OEM sheel metal welding fabrication parts

Looking for exceptionally crafted OEM sheet metal welding fabrication parts? Look no further than our factory! Get high-quality parts at competitive prices.

Request a QuotePRODUCTS DETAILS

Hot Products

High precision sheet laser cutting metal parts

High precision CNC punching metal parts

High quality custom metal fabrication welding parts

Welding parts with assembly service

CNC metal sheet bending parts

High quality plasma and flame cutting part

OEM sheel metal welding fabrication parts

Surface treatment Service by painting powder coating galvanization

Robort welding sheet fabricated parts

OEM customized high precision CNC machining metal parts

Contact us

Please feel free to give your inquiry in the form below We will reply you in 24 hours