Expert Laser Cutting and Bending Services for Precise Results

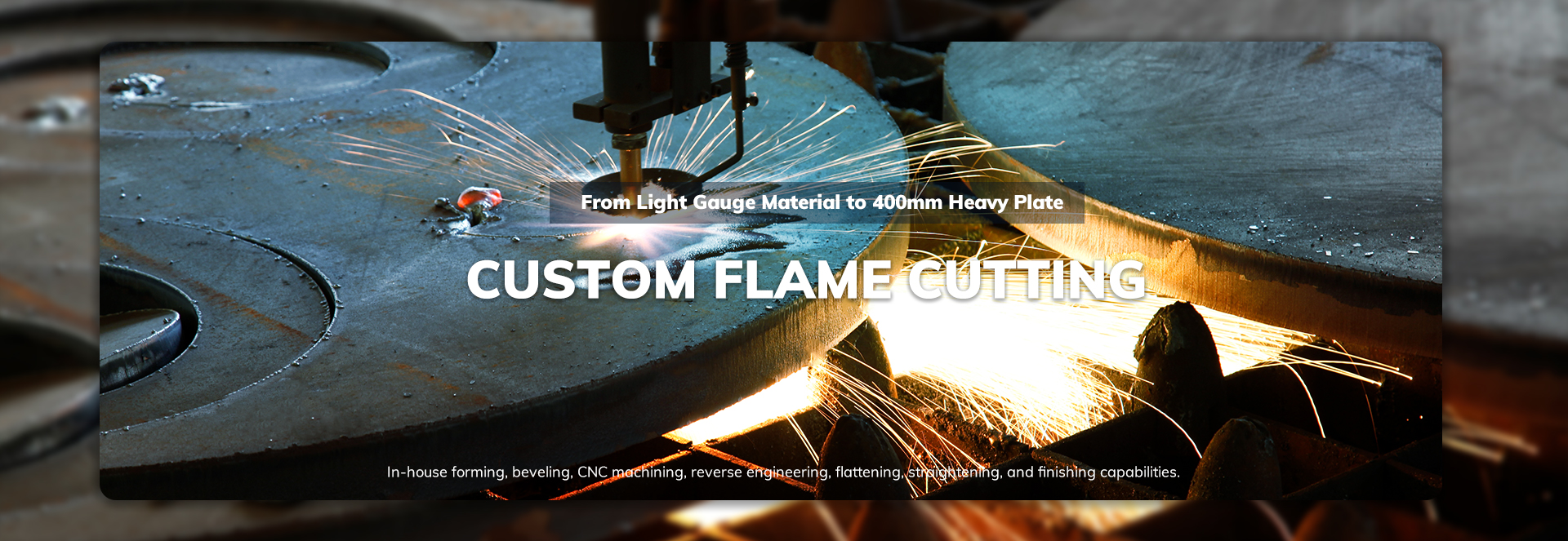

Laser Cutting and Bending Services Foster Innovation and Growth in Manufacturing IndustryAs the manufacturing industry continues to advance and innovate, the need for efficient and precise laser cutting and bending services becomes increasingly significant. These technologies have revolutionized the manufacturing process by allowing for faster, more accurate parts production and customization. With the latest laser cutting and bending technologies, manufacturers are able to create complex designs and shapes that were previously impossible, ushering in a new era of creativity and efficiency in manufacturing.One company at the forefront of this technological revolution is [company name], a leading provider of laser cutting and bending services. With state-of-the-art equipment and experienced staff, the company has established itself as a reliable and efficient partner for manufacturers in a wide range of industries.Laser cutting is a non-contact process that uses a high-powered laser to cut through various materials, including metals, plastics, and composites. This method produces clean and precise cuts, with minimal waste and distortion. Laser cutting is ideal for creating intricate designs and shapes, making it a popular choice for industries such as aerospace, automotive, and electronics.One of the most significant advantages of laser cutting is its ability to create complex designs with high precision. This allows manufacturers to create parts with tight tolerances, resulting in a more efficient and reliable final product. In addition, laser cutting is much faster than traditional cutting methods, reducing production times and increasing output.Bending is another critical process in manufacturing, and it has also benefited greatly from technological advancements. The latest bending machines use computer-controlled systems to accurately bend and shape metal parts. This technology allows for precise and repeatable bends, with minimal setup time, reducing wastage and material costs.The combination of laser cutting and bending has revolutionized the manufacturing industry, making it possible to produce parts and components with greater accuracy and efficiency than ever before. Manufacturers are now able to create complex shapes and designs, all while keeping production times and costs low.[company name] offers a wide range of laser cutting and bending services to meet the unique needs of their customers. The company has invested heavily in the latest technology to ensure that they can offer the most accurate and efficient services possible. With their advanced equipment and experienced staff, they are able to handle projects of all sizes and complexities.In addition to their laser cutting and bending services, [company name] offers a range of value-added services, including design consultation, prototype development, and assembly. This allows their customers to enjoy a full range of services, from initial product development to final assembly and delivery.The company's commitment to quality and customer satisfaction has earned them a reputation as a reliable and innovative partner for manufacturers in all industries. They work closely with their clients to ensure that their needs are met and that the final product meets the highest standards of quality.In conclusion, laser cutting and bending services are essential for modern-day manufacturing, and companies like [company name] play a critical role in meeting the growing demand for these services. With their advanced technology and innovative solutions, they are helping manufacturers to innovate and grow, creating products that are more efficient, reliable, and affordable than ever before.

Read More

Highly Efficient Precision Laser Cutter for Metals: Cut Steel, Aluminum, Copper, and Titanium With Ease Using Advanced Fiber Laser Technology - Mechanical Kingdom

Precision Laser Cutting: Unlocking New Possibilities with SS Laser CuttingWhen it comes to precision cutting, Ss stainless steel is one of the most challenging materials to work with. But with the rise of advanced laser cutting technology, what was once considered difficult has now become achievable with ease. One such technology is the Fy4050b Precision Laser Cutter from Feiyue Laser.The Fy4050b Precision Laser Cutter is a top-of-the-line CNC cutting machine that can handle a variety of materials, including stainless steel plates, aluminum, copper, titanium sheets, and jewelry metal. What sets this machine apart is its fixed optical path design, which provides a maintenance-free optical path and low operating cost while delivering high processing efficiency and cutting quality. Equipped with an international advanced fiber laser, the Fy4050b machine is capable of cutting through thick metal sheets with precision and accuracy, providing you with clean and smooth edges that require minimal post-processing. This makes it ideal for a range of applications, from industrial to jewelry making.The cutting head of the Fy4050b machine uses the LASERMECH optical fiber cutting head imported from the United States. It's also fitted with a capacitive sensor, which provides high sensing accuracy, sensitive response, and stable and reliable performance. This means you get a quality cut every time, regardless of the shape or size of the material.The CNC system of the Fy4050b machine is specially designed for laser cutting. It uses an imported non-contact height tracking system that's sensitive and accurate, and is not affected by the shape of the material. This helps to eliminate potential errors during the cutting process, ensuring that you get precise and clean cuts every time. Overall, the Fy4050b Precision Laser Cutter is a valuable investment for anyone looking to get into laser cutting. It's affordable, versatile, and reliable, making it a great choice for businesses and hobbyists alike. With its exceptional cutting quality and high processing efficiency, this machine is sure to unlock new possibilities in your metal cutting projects.In conclusion, choosing the right laser cutter is crucial, especially when it comes to working with tough materials like Ss stainless steel. With the Fy4050b Precision Laser Cutter from Feiyue Laser, you're assured of a quality machine that can handle all your metal cutting needs with ease, precision, and efficiency. This cutting-edge technology is transforming the metal-cutting industry, making it easier and more affordable to achieve precision cuts than ever before. So, invest in the Fy4050b Precision Laser Cutter today and take your metal cutting projects to a whole new level!

Read More

Expert Steel Fabricators: Providing Top-Quality Steel Services" could be rewritten as "Premium Steel Fabrication Services: Delivering Exceptional Results" without mentioning the specific brand name.

Steel Fabrication Services, a leading provider of high-quality steel fabrication solutions, is revolutionizing the industry with its cutting-edge technology and exceptional customer service. With years of expertise and a commitment to innovation, the company has become synonymous with excellence in the field.Specializing in custom-made fabricated steel products, Steel Fabrication Services caters to a wide range of industries including construction, manufacturing, oil and gas, and infrastructure. The company offers a diverse range of services such as structural steel fabrication, welding, and engineering design. From large-scale projects to small tailor-made solutions, their team of highly skilled professionals ensures top-notch quality and timely delivery every time.One of the main factors that sets Steel Fabrication Services apart from its competitors is its state-of-the-art manufacturing facility equipped with the latest technology. The company utilizes advanced computer-aided design (CAD) software and high-precision machinery to deliver accurate and finely crafted steel products. This combination of cutting-edge technology and skilled craftsmanship allows for the production of complex and intricate steel structures that meet the highest standards of quality and precision.In addition to its advanced manufacturing capabilities, Steel Fabrication Services takes great pride in its commitment to customer satisfaction. The company understands that every client has unique requirements and works closely with them to provide tailored solutions that fulfill their specific needs. With a customer-centric approach, Steel Fabrication Services aims to build long-term relationships with its clients based on trust and mutual success.An integral part of Steel Fabrication Services' success is its team of highly trained and experienced professionals. The company employs a dedicated workforce that is passionate about what they do and strives for excellence in every project. From project managers to welders, every member of the team plays a crucial role in ensuring the highest level of workmanship and attention to detail.Furthermore, Steel Fabrication Services is committed to maintaining the highest industry standards and certifications. The company follows strict quality control procedures to ensure that all steel products meet or exceed customer expectations and industry regulations. With a strong emphasis on safety and efficiency, Steel Fabrication Services consistently delivers safe and reliable steel solutions to its clients.The company's dedication to innovation and continuous improvement is reflected in its investment in research and development. Steel Fabrication Services constantly seeks new ways to enhance its manufacturing processes and efficiency, resulting in cost-effective solutions for its clients without compromising on quality. By staying at the forefront of technological advancements, the company maintains its competitive edge in the industry.As an environmentally conscious organization, Steel Fabrication Services strives to minimize its carbon footprint. The company implements sustainable practices throughout its operations and consistently explores ways to reduce waste and promote energy efficiency. By adopting eco-friendly approaches, Steel Fabrication Services contributes to a greener future while providing top-notch steel fabrication solutions.With its exceptional services, state-of-the-art technology, and commitment to customer satisfaction, Steel Fabrication Services continues to lead the way in the steel fabrication industry. As the company looks towards the future, it remains focused on innovation, quality, and providing customized solutions to meet the evolving needs of its clients.In conclusion, Steel Fabrication Services is a trusted name in the steel fabrication industry, offering a wide range of high-quality products and services. With its advanced technology, skilled workforce, and customer-centric approach, the company strives to exceed customer expectations and deliver excellence in every project.

Read More

Top Small Metal Fabrication Techniques and Services for All Your Needs

Title: Small Metal Fabrication Company Revolutionizes the Industry with Expertise and Cutting-Edge TechnologyIntroduction:In an era where the manufacturing industry is rapidly evolving, one company has managed to disrupt the metal fabrication sector through its exceptional prowess and innovative technology. This revolutionary company, which prefers to remain anonymous, aims to transform the way we perceive small metal fabrication. With its commitment to precision, efficiency, and customer satisfaction, the company has become a pioneer in shaping the future of metalworks.Body:I. A Tradition of Excellence:Small Metal Fabrication has a rich history dating back several decades, during which it has established itself as an industry leader. With an unyielding dedication to quality, the company has consistently produced superior metal products for a variety of applications. Small Metal Fabrication's commitment to excellence has earned it recognition as a trusted partner by numerous clients across different sectors, ranging from automotive and aerospace to electronics and construction.II. Innovating the Fabrication Process:Integral to the company's success lies its relentless pursuit of innovation. Investing heavily in advanced technology, Small Metal Fabrication has transformed the traditional fabrication process into a highly efficient, precise, and cost-effective system. By leveraging cutting-edge machinery, automation, and robotics, the company has significantly reduced production time and minimized errors, ensuring consistent quality and higher productivity.III. Expert Team and State-of-the-Art Facilities:Central to Small Metal Fabrication's ability to deliver exceptional results is its highly skilled and experienced team. With a passion for metalworks, the company's personnel are experts in their respective fields, meticulously trained to handle intricate projects with utmost precision. Moreover, the company's state-of-the-art facilities provide an ideal environment for their experts to bring their visions to life.IV. Customization and Flexibility:Understanding the unique demands of its diverse clientele, Small Metal Fabrication excels in providing tailor-made solutions for each project. The company's flexible production capabilities enable them to accommodate various specifications, size requirements, and design preferences. This commitment to customization sets the company apart and has contributed to its long-standing client relationships.V. Sustainability and Eco-Friendly Practices:Small Metal Fabrication is acutely aware of its responsibility towards the environment. In an effort to contribute to a sustainable future, the company actively implements eco-friendly policies throughout its operations. Reusable materials, responsible waste management, and energy-efficient practices are just a few examples of Small Metal Fabrication's dedication to minimizing its ecological footprint.VI. Industry Recognition and Awards:Proving its industry dominance and commitment to excellence, Small Metal Fabrication has garnered several industry awards and accolades. Its dedication to innovation, customer satisfaction, and sustainable practices has earned the company widespread recognition and the trust of clients and partners alike. These prestigious awards further cement Small Metal Fabrication's reputation as a leading force in metal fabrication.VII. Looking Ahead:As the industry continues to evolve, Small Metal Fabrication remains at the forefront of innovative metalworks solutions. By staying abreast of technological advancements and continuously honing their skills, the company remains well-positioned to meet the ever-changing demands of their clients. Through their unwavering commitment to quality, customization, and sustainability, Small Metal Fabrication is poised to leave an indelible mark on the metal fabrication industry.Conclusion:Small Metal Fabrication's unwavering dedication to excellence and innovation has revolutionized the metal fabrication industry. With its cutting-edge technology, expert team, and commitment to sustainability, the company continues to lead the way in providing tailor-made metal products for a vast array of industries. Small Metal Fabrication's legacy as a pioneer in the field is secure, as they continue to shape the future of metal fabrication with their relentless pursuit of perfection.

Read More

Benefits of Large Format Laser Cutting Services for Your Business

Large Format Laser Cutting Service Revolutionizes Precision Cutting in the Manufacturing IndustryIn recent years, the manufacturing industry has witnessed a significant boom, fueled by technological advancements that have revolutionized production processes. One such innovation that is making waves is the Large Format Laser Cutting Service, offered by a pioneering company. This cutting-edge service has garnered widespread attention due to its ability to provide unparalleled precision cutting, enabling manufacturers to create intricate designs and bring their visions to life in a whole new way.The Large Format Laser Cutting Service utilizes state-of-the-art laser technology that can cut through a wide range of materials with utmost accuracy. Whether it is metal, wood, acrylic, or even fabric, this service ensures a flawless outcome that meets the highest industry standards. By employing a large-format laser cutting machine, manufacturers no longer have to worry about limitations in size or design complexity. With this cutting-edge technology, they can now take on projects of any scale, confidently pushing the boundaries of creativity and customization.The company behind this remarkable service, {}, is a recognized leader in the laser cutting industry. They pride themselves on their commitment to delivering cutting solutions that are both advanced and versatile, catering to the diverse needs of their clients. With a team of highly skilled technicians and state-of-the-art equipment, they have established themselves as a trusted partner for manufacturers seeking innovative cutting solutions.What sets {} apart from their competitors is their relentless pursuit of excellence and their unwavering dedication to customer satisfaction. The company understands that every project is unique and requires a tailored approach. Therefore, their team works closely with clients, offering expertise and guidance to ensure that the final outcome exceeds expectations.The Large Format Laser Cutting Service provided by {} offers several key advantages over traditional cutting methods. Firstly, it eliminates the need for molds, thereby reducing costs and production time significantly. Manufacturers can now create intricate cuts and complex designs without the constraints imposed by traditional cutting techniques, saving both time and money. Additionally, this service allows for highly precise, clean cuts, resulting in finished products of the highest quality.One industry that has greatly benefited from this cutting-edge technology is the automotive sector. With the increasing demand for customized designs and unique features, the Large Format Laser Cutting Service has become an invaluable tool for automotive manufacturers. It enables them to create intricate patterns, precise logos, and unique shapes that were once deemed unattainable. The service also facilitates the production of lightweight parts, contributing to the overall fuel efficiency and performance of vehicles.The furniture industry has also embraced the Large Format Laser Cutting Service, as it offers unparalleled precision in cutting both wood and acrylic. This allows manufacturers to create intricate designs and patterns that were previously only possible through manual labor, saving both time and costs. Moreover, the service enables furniture designers to unleash their creativity, resulting in pieces that are not only aesthetically pleasing but also structurally robust.The applications of the Large Format Laser Cutting Service are not limited to just the automotive and furniture industries. It has found use in industries as diverse as signage, electronics, aerospace, and architecture. The versatility of this service has opened up a world of possibilities for manufacturers, empowering them to create products that are truly extraordinary.With the continuous advancement of laser technology, the possibilities for the Large Format Laser Cutting Service seem limitless. As manufacturers continue to push the boundaries of design and customization, this service will undoubtedly play a pivotal role in shaping the future of the manufacturing industry. With {} at the forefront of this innovation, manufacturers can expect nothing less than cutting-edge solutions that redefine precision cutting.

Read More

Highly Efficient 3 Axis CNC Vertical Machining Center Unveiled in China's Manufacturing Industry

China's 3 Axis CNC Vertical Machining Center has taken the manufacturing industry by storm. This specialized machine is designed to be used by manufacturers who want to deliver consistent precision and accuracy in their production processes. The technology behind this equipment is a marvel, and the manufacturers of this CNC Machining Center have refined it to near perfection.The Chinese manufacturer behind this innovative product has built a strong reputation for delivering high-quality machines that help revolutionize manufacturing processes. Their deep understanding of the industry's needs, coupled with their focus on innovative and cutting-edge technology, has seen them feature prominently in the industry's success stories.Like many of their machines, the 3 Axis CNC Vertical Machining Center is built to handle large volumes of material. It is ideal for a wide range of industries such as automotive, aerospace, medical devices, and many more, where precision and accuracy are critical.The 3 Axis CNC Vertical Machining Center is designed with the user in mind. It is easy to operate, and the user interface is intuitive, eliminating the need for specialized training. This machine is a perfect fit for users who want to optimize their process as it enables them to deliver higher quality products quickly.One of the standout features of this machine is that it can handle complex and intricate shapes and designs. With the 3-axis configuration, this machining center allows for multi-dimensional cutting, which provides the user with a wide range of processing capabilities.Another notable feature of this machining center is the spindle speed. The spindle speed is an important aspect of machining, and the 3 Axis CNC Vertical Machining Center delivers on this. It has a high speed, and the spindle can handle a wide range of materials, including steel, copper, and aluminum. This means that manufacturers can process materials with a high degree of efficiency since they can handle varying degrees of hardness.In addition, this machine is highly versatile. Its configuration can be customized to meet specific production requirements. Whether it's a varying range of material types or shapes, the 3 Axis CNC Vertical Machining Center is a machine you can count on to deliver precision and accuracy with every cut.The Chinese manufacturer of this machine has demonstrated their commitment to delivering machines that are not only efficient, but that help customers achieve excellence in their manufacturing processes. They have invested in research and development to ensure this machine aligns with the latest technological advancements. They are always looking for ways to make their machines more efficient and more effective.Through their extensive network of authorized dealers and support mechanisms, the Chinese manufacturer ensures that customers get the support they need to optimize their processes. They offer technical support, machine maintenance, and a wide range of spare parts associated with their machines.Overall, the 3 Axis CNC Vertical Machining Center is a machine that is setting new standards in the manufacturing industry. With its high precision, versatility, and efficiency, it is no surprise that it has become a popular choice for manufacturers and businesses in various industries. The Chinese manufacturer behind this machine has proven to be a reliable partner for businesses looking to refine their processes, and with their commitment to excellence, we can expect more innovative products from them in the future.

Read More

Reliable Metal Forming Services Revamp Manufacturing Processes for Enhanced Efficiency

Metal Forming Services, a renowned manufacturer in the metalworking industry, continues to revolutionize the sector with its cutting-edge technology and efficient solutions. With a dedicated team of experts and state-of-the-art facilities, the company has built a strong reputation for delivering high-quality products and exemplary customer service.Metal Forming Services is committed to meeting the growing demands of various industries, including automotive, aerospace, and construction. They offer a wide range of metal forming services, such as stamping, bending, and deep drawing. Their advanced equipment and skilled technicians allow them to tackle complex projects with precision and consistency.One of Metal Forming Services' key strengths lies in their ability to customize solutions that meet individual client specifications. They understand that every project is unique and requires a tailored approach. Through close collaboration with customers, they gather detailed requirements and provide innovative solutions that fulfill their specific needs.The company's commitment to cutting-edge technology has been instrumental in their success. They continuously invest in the latest equipment, allowing them to stay at the forefront of the industry. By embracing automation and digitalization, Metal Forming Services ensures increased efficiency, reduced lead times, and enhanced product quality.Moreover, Metal Forming Services prioritizes sustainability and adopts environmentally friendly practices throughout their operations. They understand the importance of minimizing their ecological footprint and strive to make a positive impact on the environment. From employing energy-efficient machinery to recycling waste materials, they are dedicated to promoting sustainability in the metalworking industry.As a customer-centric company, Metal Forming Services places great emphasis on delivering exceptional service. They value their relationships with clients and strive to exceed expectations at every opportunity. Their knowledgeable and friendly staff are always available to address any concerns and provide prompt assistance, making the customer experience seamless and enjoyable.To ensure consistent excellence, Metal Forming Services employs a rigorous quality control process. They adhere to stringent industry standards and implement stringent quality assurance measures. With a comprehensive inspection system in place, they guarantee that every product leaving their facility meets or exceeds the highest quality benchmarks.In addition to their commitment to quality, Metal Forming Services believes in fostering a culture of safety in the workplace. They prioritize the well-being of their employees and strictly adhere to safety protocols to minimize accidents and injuries. By providing a safe and secure working environment, they promote employee satisfaction and productivity.Metal Forming Services also prides itself on its continuous commitment to research and development. They understand the importance of staying ahead of technological advancements and industry trends. Through ongoing innovation and learning, they anticipate emerging needs and deliver solutions that cater to the evolving demands of their customers.As a market leader in the metalworking industry, Metal Forming Services continues to set the benchmark for excellence. Their unwavering dedication to customer satisfaction, technological innovation, and sustainable practices ensures that they remain at the forefront of the industry. With each project they undertake, they strive to create lasting partnerships and deliver unparalleled value to their clients.In summary, Metal Forming Services is a dynamic and forward-thinking manufacturer that offers a comprehensive range of metal forming services. With their state-of-the-art facilities, skilled workforce, and commitment to quality, the company consistently delivers exceptional solutions to a diverse clientele. Through their ongoing investment in technology and environmentally friendly practices, Metal Forming Services sets itself apart as an industry leader that is capable of meeting the ever-changing demands of modern manufacturing.

Read More

Trendy Steel and Fabrication Options for Your Projects

Steel And Fabrication Company Joins Forces with Leading ManufacturerThe [Company Name] is proud to announce its recent collaboration with a leading manufacturer in the industry. This partnership is set to establish a unique and innovative approach to steel fabrication that will further elevate the company's position as a leader in the field.With decades of experience in steel fabrication, [Company Name] has been revered for its high-quality products and exceptional customer service. The company has built a strong reputation for its ability to handle a wide range of projects, from small-scale custom fabrications to large industrial constructions. By providing clients with personalized solutions and superior craftsmanship, [Company Name] has consistently proven itself to be a top choice for steel fabrication needs.The recent partnership with the leading manufacturer comes as an exciting development for [Company Name]. With a shared commitment to excellence and cutting-edge innovation, this collaboration is expected to yield groundbreaking results in the industry. By combining resources and expertise, the two companies aim to deliver even more advanced and efficient solutions to their clients.One of the key benefits of this collaboration is the expanded range of capabilities that will be available to clients. The partnership will enable [Company Name] to leverage the manufacturer's state-of-the-art technologies and advanced materials, allowing for the creation of even more complex and intricate designs. This will ultimately translate to greater flexibility and creativity in meeting the diverse needs of customers.Furthermore, the collaboration will also result in enhanced efficiency and cost-effectiveness. By streamlining processes and optimizing resources, [Company Name] will be able to offer competitive pricing without compromising on quality. Clients can expect to receive the same level of excellence they have come to expect from [Company Name], but with added value and affordability.In addition to technological advancements, the partnership will also foster a culture of continuous improvement within [Company Name]. Through knowledge sharing and best practices exchange, the company will further bolster its internal capabilities and elevate its standards of operation. This will ultimately benefit clients, as they will be met with heightened levels of professionalism and proficiency.Another significant aspect of this collaboration is the emphasis on sustainability and environmental responsibility. Both [Company Name] and the leading manufacturer are committed to minimizing their ecological footprint and promoting sustainable practices. By working together, they will explore new ways to integrate eco-friendly materials and processes into their operations, thereby contributing to a greener and more sustainable industry.The leadership team at [Company Name] is enthusiastic about the prospects of this collaboration and the positive impact it will have on their clients. By aligning with a reputable and forward-thinking partner, [Company Name] is reinforcing its commitment to providing unparalleled service and staying at the forefront of the industry.As for the leading manufacturer, they see this partnership as an opportunity to further expand their reach and influence within the market. By teaming up with [Company Name], they will have a trusted and capable partner to help them realize their vision of delivering top-notch solutions to a wider audience.In conclusion, the collaboration between [Company Name] and the leading manufacturer represents a significant milestone for the steel fabrication industry. This partnership is set to drive progress and innovation, ultimately benefiting clients and setting a new standard for excellence in the field. As the two companies embark on this new chapter together, they look forward to the exciting possibilities that lie ahead.

Read More

Expert Welding Services: Connect with Us for Information and Support

Read More